Guide pins are essential mechanical components used in machinery for precise alignment and positioning, ensuring accuracy and preventing damage during manufacturing processes.

What Are Guide Pins?

Guide pins are precision-engineered components used in machinery to ensure accurate alignment and positioning of parts or tools during manufacturing processes. Typically cylindrical or conical in shape, these pins are designed to fit into corresponding holes or bushings, guiding components into the correct position to prevent misalignment and potential damage. Made from durable materials like hardened steel, guide pins are crucial for maintaining precision in operations such as machining, assembly, and mold making. Their smooth surface finish and tight tolerances ensure consistent performance, making them an essential element in achieving high-quality results in various industrial applications.

Importance of Guide Pins in Machinery

Guide pins play a crucial role in machinery by ensuring precise alignment and positioning of moving or interchangeable parts. They minimize the risk of misalignment, which can lead to costly damage or downtime. By guiding components accurately, they enhance operational efficiency and reduce wear and tear on equipment. In machining and assembly processes, guide pins are essential for maintaining tight tolerances and ensuring high-quality finished products. Their presence also improves safety by preventing accidents caused by improper alignment. Across various industries, guide pins are indispensable for achieving consistent and reliable results in high-precision applications.

Types of Guide Pins

Guide pins are categorized into cylindrical, conical, and diamond-shaped types, each offering distinct alignment benefits in machinery and manufacturing processes.

Cylindrical Guide Pins

Cylindrical guide pins are smooth, straight, and typically made from high-grade steel for durability. They are widely used in machinery and manufacturing for precise alignment, offering minimal friction and easy installation. Their simple design makes them ideal for applications requiring consistent positioning and stability. Often employed in CNC machines and fixtures, cylindrical guide pins ensure accurate fitting and prevent damage during production processes. They are cost-effective and easy to maintain, making them a popular choice in various industries. Their versatility and reliability contribute significantly to efficient manufacturing operations, ensuring components fit together seamlessly and reducing wear and tear over time.

Conical Guide Pins

Conical guide pins are tapered pins designed to assist in aligning and positioning components during assembly or machining. Their unique shape allows for self-centering, making them ideal for applications where precise alignment is critical. Often used in mold making and CNC machining, conical guide pins provide a secure fit and reduce the risk of misalignment. They are typically made from hardened steel for durability and may feature coatings like chrome plating for added wear resistance. These pins are particularly useful in tight spaces or when guiding components into position, ensuring accuracy and efficiency in manufacturing processes. Their versatility makes them a valuable tool in various industrial applications.

Diamond-Shaped Guide Pins

Diamond-shaped guide pins are specialized fasteners featuring a unique, angular design that enhances alignment precision. Their four-sided geometry allows for secure fitment in corresponding holes, minimizing lateral movement. Commonly used in high-precision applications such as tooling and mold making, these pins are ideal for tight spaces where conventional pins may not suffice. Made from hardened steel for durability, they often feature coatings like chrome or titanium nitride to resist wear. Diamond-shaped guide pins are particularly valued in industries requiring exact positioning, such as aerospace and automotive manufacturing, ensuring components align accurately during assembly or machining processes. Their distinctive shape and robust construction make them a reliable choice for demanding environments.

Materials and Coatings

Guide pins are typically made from high-strength steel or carbide for durability. Coatings like titanium nitride or chrome enhance wear resistance, ensuring longevity in industrial applications.

Common Materials Used

Guide pins are commonly crafted from high-strength materials such as hardened steel, stainless steel, and tungsten carbide. These materials ensure durability and resistance to wear and tear. Steel alloys are frequently used for their excellent mechanical properties, while carbide offers superior hardness for demanding applications. In some cases, ceramic or polymer materials are employed for specific environmental requirements, such as corrosion resistance or high-temperature stability. The choice of material depends on the operational conditions, ensuring optimal performance and longevity of the guide pins in various machinery and manufacturing processes.

Coatings for Enhanced Durability

To enhance the longevity and performance of guide pins, various coatings are applied. Titanium nitride (TiN) is a popular choice, offering exceptional hardness and wear resistance. Chrome plating is another common option, providing a smooth surface and corrosion resistance. Nitride and phosphate coatings are also used to improve durability and reduce friction. These coatings protect guide pins from wear, corrosion, and environmental factors, ensuring consistent performance in harsh conditions. By extending the lifespan of guide pins, these coatings contribute to overall machinery efficiency and reduce maintenance costs. Properly coated guide pins maintain precision and reliability in industrial applications.

Applications of Guide Pins

Guide pins are widely used in machinery, manufacturing, and assembly processes to ensure precise alignment and positioning of components, enhancing operational efficiency and accuracy across various industries.

Role in Machining Processes

In machining, guide pins play a crucial role by ensuring precise alignment of tools and workpieces, preventing misalignment and material damage. They are often used in CNC machines and jigs, guiding drills and cutters accurately. This precision is vital for producing components with tight tolerances. By maintaining proper positioning, guide pins reduce errors and improve the overall quality of the finished product. Their use minimizes the risk of costly rework and enhances operational efficiency in manufacturing environments. This makes them indispensable in achieving consistent and reliable machining results across various industrial applications.

Use in Mold Making

Guide pins are integral to mold making, ensuring precise alignment of mold halves during assembly and operation. They help maintain structural integrity, preventing misalignment that could lead to defective parts. By guiding moving components like ejector systems, they reduce wear and tear on the mold. This ensures consistent production of high-quality parts. Guide pins also facilitate smooth mold opening and closing, critical in injection molding processes. Their presence minimizes the risk of damage from improper alignment, making them indispensable in achieving accurate and durable molds for various manufacturing applications.

Other Manufacturing Processes

Guide pins play a crucial role in various manufacturing processes beyond machining and mold making. In aerospace and automotive industries, they are used to align components during assembly, ensuring precise fits and preventing damage. They are also essential in automation systems, guiding robotic arms and tooling to maintain accuracy. Additionally, guide pins are used in electronics manufacturing for aligning circuit boards and components. Their versatility extends to custom manufacturing, where they help in creating complex assemblies by ensuring proper alignment and reducing production errors. This makes guide pins indispensable in maintaining efficiency and precision across diverse manufacturing applications.

Installation and Maintenance

Proper installation involves aligning guide pins accurately and ensuring a snug fit. Regular maintenance includes cleaning, lubricating, and inspecting for wear to ensure optimal performance and longevity.

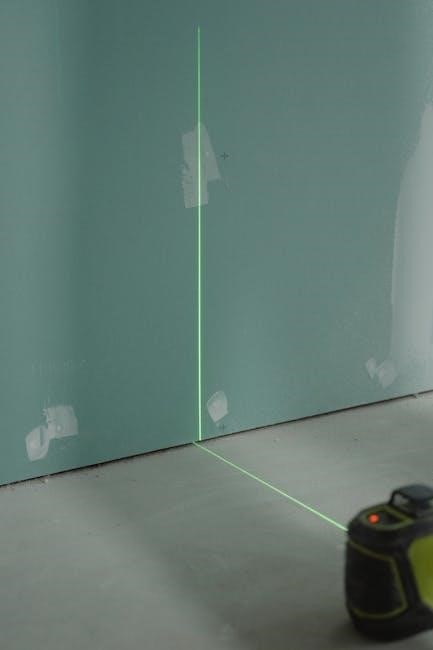

Proper Installation Techniques

Proper installation of guide pins requires precise alignment to ensure machinery operates smoothly. Start by cleaning the pin and hole to remove debris. Use a calibrated tool to align the pin with the hole, ensuring it is seated correctly. Apply a small amount of lubricant to reduce friction during insertion. Gently tap the pin into place with a soft-faced hammer to avoid damage. Once installed, verify the alignment by checking the fit and movement. Proper installation prevents wear and tear, ensuring the machinery’s accuracy and longevity. Regular checks and maintenance are also crucial to sustain optimal performance over time.

Maintenance Tips for Longevity

Regular maintenance is crucial to extend the life of guide pins. Start by cleaning the pins and surrounding areas with a non-abrasive material to remove dirt and debris. Apply a high-quality lubricant to reduce friction and prevent corrosion. Inspect the pins periodically for signs of wear, such as scoring or misalignment. Replace any damaged or worn pins promptly to avoid further damage to machinery. Store unused pins in a dry, protected environment to prevent rust. By following these maintenance tips, guide pins will perform reliably, ensuring precise alignment and smooth operation of machinery over an extended period.

Design Considerations

Design considerations for guide pins involve material selection, diameter accuracy, and surface finish to ensure optimal performance and durability in various applications and proper alignment for precise machinery operation.

Selecting the Right Diameter

Selecting the right diameter for guide pins is crucial for functionality and longevity. The diameter must match the application’s requirements, ensuring proper fit without excessive stress. Too small a pin may lead to misalignment, while too large can cause jamming or damage. Material strength and load-bearing capacity also influence diameter choice. Standard sizes are available, but custom options can be tailored for specific needs. Proper tolerancing ensures smooth operation and minimizes wear. Consulting manufacturer guidelines or engineering standards is recommended to optimize performance and durability in machinery and manufacturing processes.

Surface Finish Requirements

Surface finish is critical for guide pins to ensure smooth operation and longevity. A polished or plated finish reduces friction and wear, enhancing performance. The surface roughness, measured in micrometers, must meet specific tolerances to prevent misalignment. A smoother finish minimizes the risk of seizing or galling, especially in high-precision applications. Coatings like chrome or nitride can further improve durability. Improper surface finishes can lead to premature wear and operational issues. Always adhere to manufacturer specifications or industry standards for optimal results. Proper surface preparation ensures reliable performance in machinery and manufacturing processes.

Common Challenges

Guide pins often face issues like wear, misalignment, and corrosion, which can affect their precision and durability in machinery. Proper maintenance and material selection are crucial to mitigate these challenges effectively.

Wear and Tear Issues

Wear and tear on guide pins are common due to frequent use, high friction, and exposure to harsh environments. Over time, this leads to surface degradation, reducing their alignment accuracy. Factors contributing to wear include improper lubrication, misalignment, and the use of unsuitable materials. Regular inspection and maintenance are essential to identify signs of wear early, preventing machinery downtime. Replacing worn pins promptly ensures operational efficiency and precision. Coatings like chromium or titanium nitride can enhance durability, while proper installation techniques minimize friction. Addressing wear issues proactively is critical to maintaining the overall performance and longevity of machinery components.

Alignment and Fit Problems

Misalignment and improper fit are common challenges with guide pins, often caused by incorrect installation or uneven surfaces. When pins are not perfectly aligned, machinery performance suffers, leading to inaccurate positioning and potential damage. Poor fit can result from using pins with incorrect diameters or insufficient surface preparation. Regular inspection and precise installation techniques are critical to ensuring proper alignment. Using guide pins made from durable materials and applying appropriate coatings can mitigate these issues. Addressing alignment and fit problems promptly prevents operational disruptions and extends the lifespan of machinery components.

Safety Tips

Always wear gloves when handling guide pins to avoid cuts and injuries. Store them in a dry, secure location to prevent rust and damage.

Handling Guide Pins Safely

Always wear heavy-duty gloves when handling guide pins to protect against sharp edges and potential cuts. Use the correct tools to avoid slipping or damaging the pins. Ensure proper lifting techniques to prevent physical strain. Inspect guide pins before use for any signs of wear or damage. Store them in a dry, secure location to avoid rust and contamination. Use protective cases or containers during transportation to prevent damage. Regularly clean guide pins to remove dirt or debris that could affect performance; Follow manufacturer guidelines for handling and maintenance to ensure longevity and reliability. Proper care ensures safety and optimal functionality in machinery operations.

Proper Storage Methods

To maintain the quality and functionality of guide pins, proper storage is essential. Store them in a clean, dry environment away from direct sunlight and moisture to prevent rust or corrosion. Use protective cases or containers with individual compartments to avoid scratching or damage. Label each container for easy identification and organization. Ensure the storage area is cool and vibration-free to preserve precision. Regularly inspect stored guide pins for signs of wear or damage. Avoid stacking pins in a way that could cause bending or misalignment. Follow manufacturer-recommended storage practices to ensure longevity and reliability. Proper storage prevents deterioration and ensures guide pins remain ready for precise operation.

Guide pins are crucial for precise alignment and positioning in machinery, ensuring efficiency and preventing damage. Proper selection and care are vital for optimal performance.

Guide pins are essential components in machinery, ensuring precise alignment and positioning. They come in various types, such as cylindrical, conical, and diamond-shaped, each suited for specific applications. Proper material selection, like hardened steel, and coatings enhance durability. Installation techniques and regular maintenance are critical for longevity. Guide pins face challenges like wear and tear, but selecting the right diameter and finish helps mitigate these issues. Understanding their design and application ensures optimal performance in machining, mold making, and other manufacturing processes. Balancing durability and precision, guide pins play a vital role in achieving accurate and efficient manufacturing outcomes.

Final Thoughts on Guide Pins

Guide pins are indispensable in modern machinery, offering precision and durability. Their versatility across various industries highlights their importance. Proper selection, installation, and maintenance ensure optimal performance and longevity. While challenges like wear exist, advancements in materials and coatings address these issues. Guide pins exemplify how small components can significantly impact manufacturing efficiency and accuracy. Their continued evolution will likely expand their applications, solidifying their role as a cornerstone in industrial processes for years to come.

Additional Resources

Explore detailed guides, technical manuals, and supplier directories for guide pins to enhance your knowledge and find reliable manufacturers and tools.

Recommended Reading

For in-depth understanding, explore technical manuals and engineering guides. These resources provide insights into design, materials, and applications, helping you make informed decisions. Additionally, case studies and industry reports offer practical examples of guide pin implementations. Websites like Machining Magazine and Mechanical Engineering Hub feature articles on precision manufacturing, which often highlight the role of guide pins. Online forums and communities, such as Reddit’s engineering subreddit, also discuss best practices and troubleshooting tips. By leveraging these resources, you can gain a comprehensive understanding of guide pins and their optimal use in various industrial settings. This knowledge is invaluable for both beginners and seasoned professionals looking to refine their expertise.

Useful Tools and Suppliers

When sourcing guide pins, consider reputable suppliers like MISUMI, McMaster-Carr, and Grainger, known for high-quality precision components. Tools like precision gauges and alignment software aid in proper installation and maintenance. For custom designs, CAD libraries and 3D modeling tools are invaluable. Additionally, consult industry-specific forums and catalogs to find suppliers catering to your needs. These resources ensure you select the right guide pins and tools, optimizing performance and durability in your applications. Regularly updated catalogs and technical support from suppliers also help in staying informed about the latest advancements in guide pin technology and materials.